Rotation Moulding, also known as rotomoulding, is an innovative manufacturing process widely used for creating hollow plastic products. This method involves heating a plastic material in a mould that is rotated on multiple axes. This guide provides an in-depth understanding of rotation moulding, its benefits, applications, and its significance in efficient manufacturing.

What is Rotation Moulding?

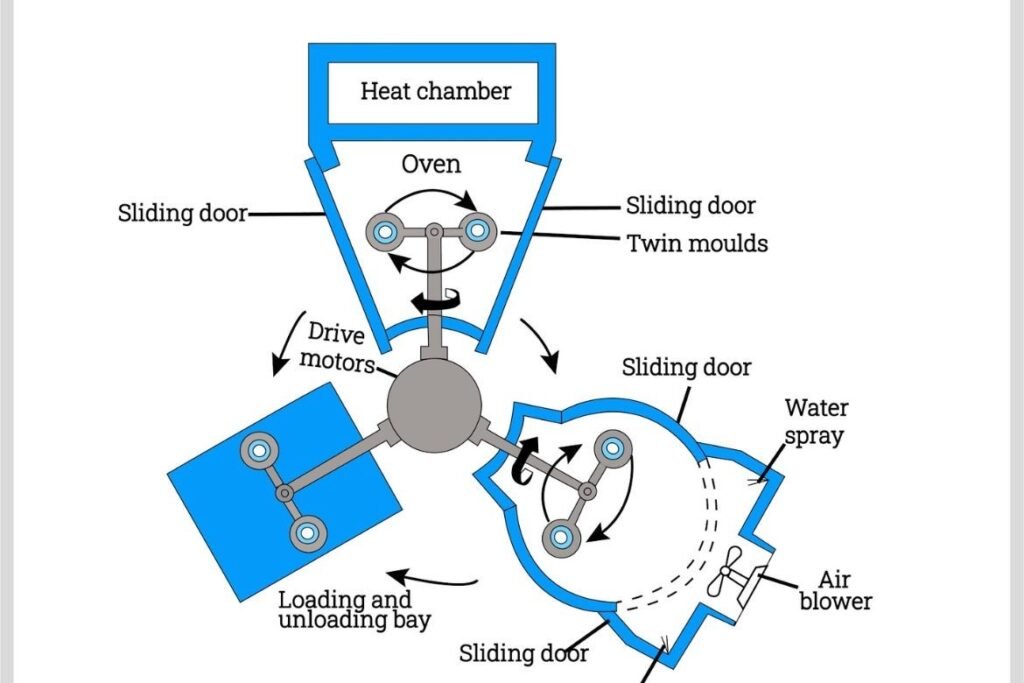

Rotation moulding is a manufacturing technique that produces hollow plastic items by rotating a heated mould. The process involves the following steps:

- Loading the Mould: A specific amount of powdered plastic is placed inside the mould.

- Heating: The mould is heated in an oven, causing the plastic to melt.

- Rotating: The mould is rotated around two perpendicular axes, allowing the melted plastic to coat the interior evenly.

- Cooling: Once the desired thickness is achieved, the mould is cooled, solidifying the plastic.

- Demoulding: The finished product is removed from the mould.

Advantages of Rotation Moulding

1. Design Flexibility

Rotation moulding allows for the creation of complex shapes and large structures. This versatility makes it suitable for a wide range of applications, from small consumer goods to large industrial containers.

2. Uniform Wall Thickness

The rotational process ensures that the wall thickness of the finished product is consistent, which is essential for durability and strength.

3. Cost-Effective Production

Compared to other moulding techniques, rotation moulding has lower tooling costs and is economical for both small and large production runs. This cost efficiency is particularly beneficial for startups and small businesses.

4. Minimal Waste

The process generates less waste because any excess plastic can often be reused in future moulding cycles, making it an environmentally friendly choice.

5. Seamless Products

Products produced through rotation moulding typically have fewer seams, resulting in stronger and more reliable items. This quality is crucial in applications where durability is essential.

Applications of Rotation Moulding

Rotation moulding is utilized in various industries, including:

- Consumer Goods: Toys, storage containers, and recreational products.

- Automotive: Fuel tanks, fenders, and other components.

- Marine: Kayaks, buoys, and other watercraft parts.

- Industrial: Custom tanks, bins, and equipment.

The Importance of Rotation Moulding in Efficient Manufacturing

In today’s competitive landscape, efficient manufacturing processes are vital. Rotation moulding stands out due to its flexibility, speed, and ability to produce high-quality products with minimal waste. By adopting rotation moulding, businesses can enhance their production efficiency, reduce costs, and meet the diverse needs of their customers.

Conclusion

Understanding Rotation Moulding is essential for anyone involved in manufacturing or product design. This technique not only offers numerous benefits, including design flexibility and cost-effectiveness, but also plays a significant role in modern manufacturing. By considering rotation moulding for your next project, you can leverage its advantages to create high-quality products efficiently. Whether you’re new to manufacturing or looking to optimize existing processes, rotation moulding is a powerful option to explore.